Biomass Gasification – Power Plants

AIR TECHNIC s.r.o. designs and builds complete biomass gasification power plants with IC engines and generators.

In the year 2015 AIR TECHNIC s.r.o. successfully completed gasification technology development. Plant and technology’s technical parameters and commercial reliability are proven in continuous operation.

Gasifier technology is registered at the Offices of Industrial Ownership of the Czech Republic under the Paragraph 11, Section 1, Item No. 478/1992 Sb., in full, inscribed in the Register as UTILIZATION SAMPLE No. 28354.

Gasifier technology is registered at the Offices of Industrial Ownership of the Czech Republic under the Paragraph 11, Section 1, Item No. 478/1992 Sb., in full, inscribed in the Register as UTILIZATION SAMPLE No. 28354.

Gasification is a termochemical conversion of carbonaceous materials (biomass) into combustible gases. This is achieved by reacting the material at high temperatures with a controlled amount of air or mixture of oxygen with steam, depending on the use of the generator gas.

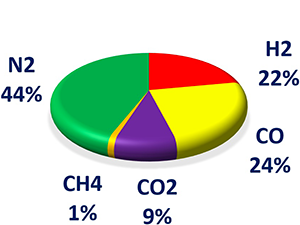

The main product of gasification is a generator gas (syngas) containing the gaseous components of H2, CO, CO2, CH4, H2O, N2, hydrocarbons and higher boiling pyrolysis products (tar) and a solid residue often containing a certain amount of carbon, dust and other compounds.

The gasifier developed by AIR TECHNIC is atmospheric, unique downdraft configuration. The gasification of the biomass is divided into zones in the gasifier – drying, pyrolysis, oxidation and reduction. The main advantage of this type gasifier is the production of syngas with low tar content for IC engines.

Output Parameters

| Power plant electrical output per one gasifier line* | 600 to 710 kWe |

|---|---|

| Parasitic electrical load | up to 12% |

| Power plant electrical efficiency – feedstock to energy | 32,0 % |

| Thermal energy generated at outside ambient temperature of t = 0°C | 600 to 710 kWt |

| Feedstock consumption at heating value of 8 MJ/kg and MC of 50 % | 0.85 – 1.00 tonne/h |

*The gasifier can also be operated at lower power

Higher electrical and thermal output is achieved by parallel arrangement of gasifier lines, i.e. syngas generators and IC engines.

Syngas Parameters

Syngas chemical composition

Syngas chemical composition

| H2 | ~ 20-25% |

|---|---|

| CO | ~ 15-30% |

| CO2 | ~ 5-15% |

| CH4 | ~ 1-3% |

| N2 | ~ 40-50% |

Syngas chemical composition

| LHV | ~ 5,0 to 6,5 MJ/Nm³ |

|---|

Feedstock Parameters

Wood chips

| Average heating value | 10.0 (8 to 12) GJ/tonne |

|---|---|

| Average moisture content | 30-50 % |

Feedstock preferred size

Fuel particle size of 8 to 80mm (ideal size of 50x50x20mm)

Maximum particle size – length 100mm, thickness 25mm (up to 10% of total volume)

Minimal particle size – 8 mm (up to 10% of total volume)

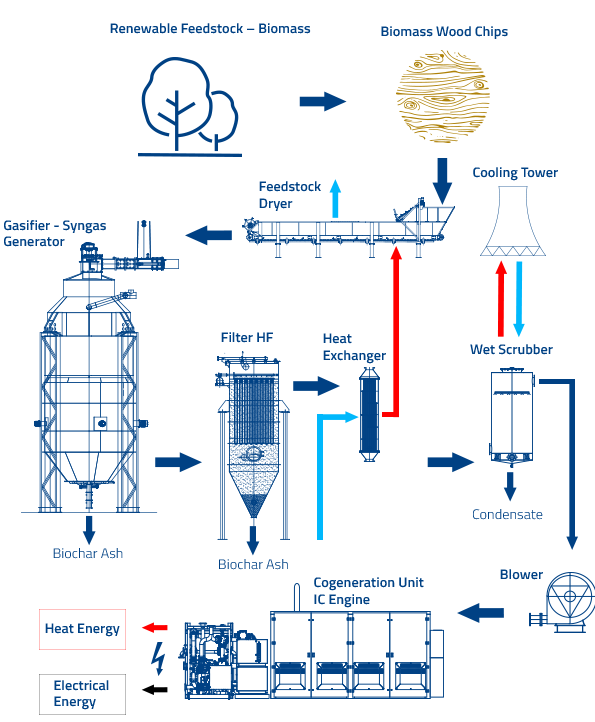

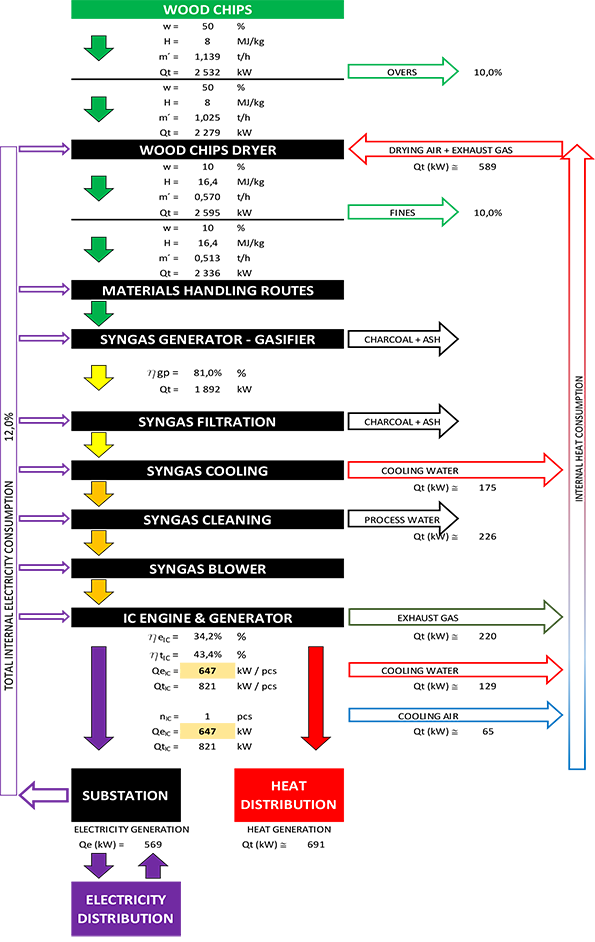

Power Plant Schema

Energy & Mass Balance

Major Components

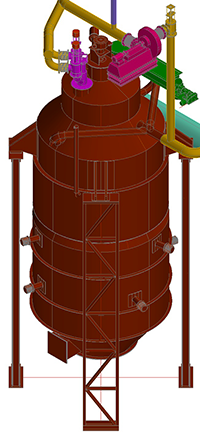

Syngas Generation

Wood chip and biomass gasification technology for syngas generation. Generated syngas is cooled and filtered prior to being fired in IC engines. Syngas generation byproduct is Biochar, which has commercial use.

IC Engines – Cogeneration Units

Cleaned and cooled syngas is used for electricity generation in IC engines coupled to electricity generators. Waste heat from IC engines cooling systems is extracted and used for feedstock drying and commercial use. Existing plants are equipped with IC engines manufactured by either ELTECO (GUASCOR – Dresser Rand) or GE Jenbacher.

Materials Handling and Feedstock Processing

Feedstock is dried in wood chips dryer. Further processing includes screening for fines, overs, tramp metals removal system and conveyors.

Instrumentation & Controls

I&C systems and monitoring allow local and remote control of individual systems and/or complete plant.

Heating and Cooling Systems

Heating and cooling systems service IC engine, syngas and other components cooling. Waste heat is further utilized for feedstock drying and commercial use.

Ventilation Systems

Ventilation system controls and distributes air for feedstock drying. Ventilation is also used for cooling of the machinery room and switchboards.

Nitrogen Generation and Distribution

Nitrogen generation and distribution system is used for syngas HF filter regeneration and pneumatic actuators.

Auxiliary Fuel Systems (LPG, natural gas, diesel)

Auxiliary fuel system is used for gasifier start-up, gasifier flare stabilization and syngas generator warm up.

Steel Structures

Gasification equipment supporting steel structures are independent of building’s structures.